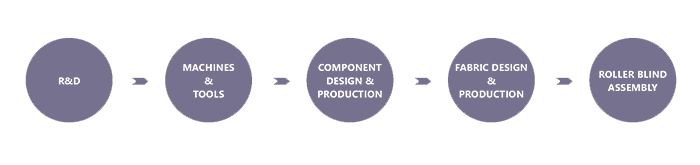

Much of Markisol’s sustained market success can be attributed our profound technical knowledge and a persistent vertical integration of our production processes. Nowadays, we are in full control of virtually every step of the way from research and development to the final assembly of finished products.

Proprietary machinery has been the hallmark of Markisol since the very start. By now, we have our own plastic injection machines and equipment for 3D printing a variety of components. Furthermore, we have our own fabric designers and a large fabric production plant. From the early beginning, the aim was to control the entire value chain – from design and engineering, components to fabrics and manufacturing.

Markisol’s strength lies in the company’s skillful use of innovation and vertical integration. From the early beginning, the aim has been to manage the entire value chain – from design and engineering, components to fabrics and manufacturing. This gives us full control over quality as well as shorten lead times for development and delivery.

© 2024 Markisol